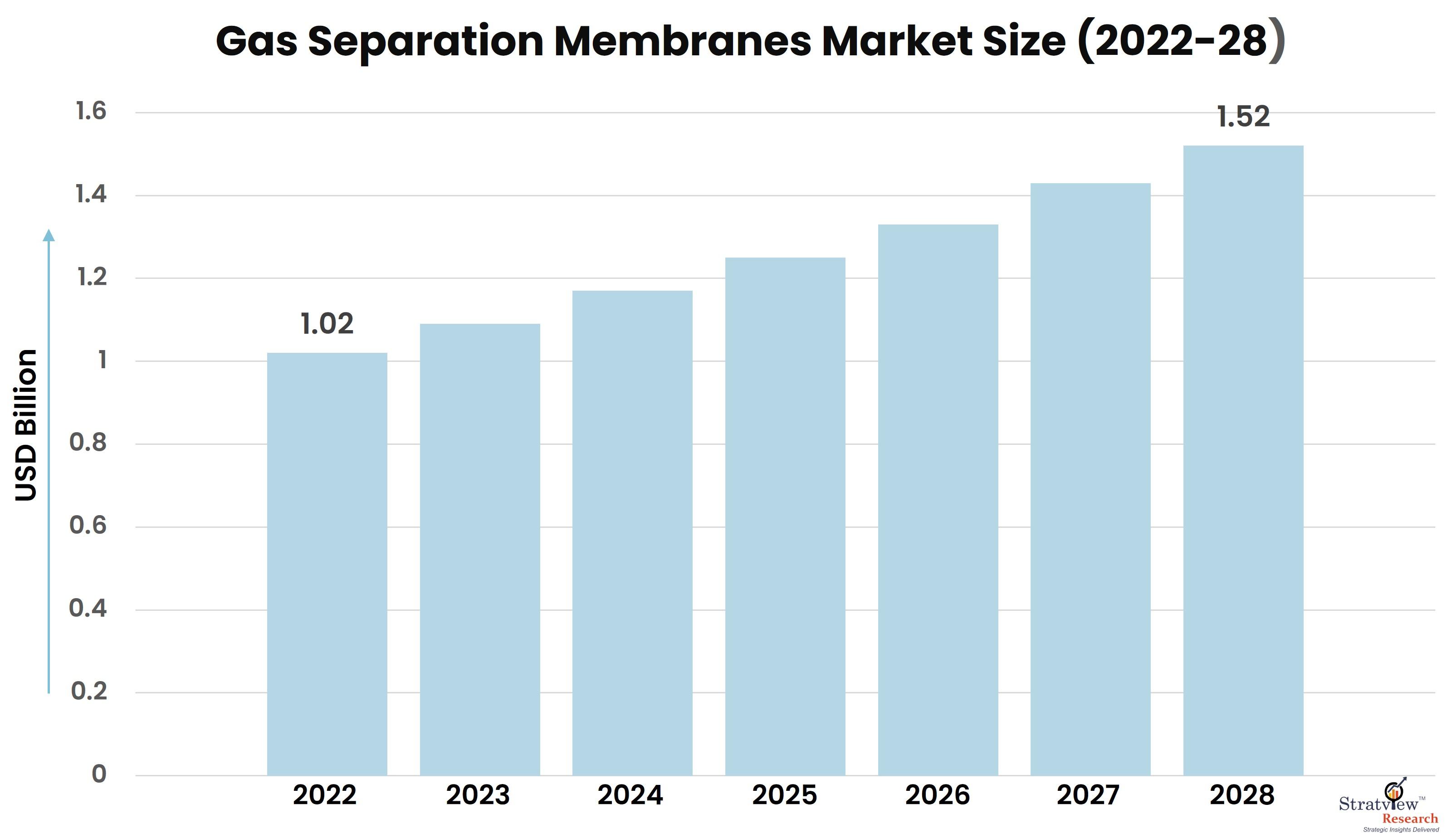

According to Stratview Research, the gas separation membranes market was estimated at USD 1.02 billion in 2022 and is likely to grow at a CAGR of 6.96% during 2023-2028 to reach USD 1.52 billion in 2028.

In an era where environmental sustainability is paramount, technologies that contribute to cleaner air and more efficient industrial processes are gaining prominence. One such innovation making waves is gas separation membranes. These membranes play a crucial role in various industries by selectively separating gases, leading to improved efficiency, reduced emissions, and a more sustainable future. This article serves as a comprehensive guide to the Gas Separation Membranes Market, exploring its applications, technologies, and the driving forces behind its rapid growth.

Understanding Gas Separation Membranes:

Gas separation membranes are advanced materials designed to selectively permeate certain gases while blocking others. This process allows for the efficient separation of gas mixtures, making it a vital technology in industries such as petrochemical, natural gas processing, air separation, and more. The membranes operate based on factors like molecular size, solubility, and diffusion rates, offering a versatile solution for various gas separation challenges.

Applications Across Industries:

Natural Gas Processing: Gas separation membranes are extensively used in natural gas processing to remove impurities and separate methane from other gases, ensuring the production of high-purity natural gas.

Petrochemical Industry: In petrochemical processes, gas separation membranes aid in the separation of hydrogen and other gases, contributing to the efficiency of various chemical processes.

Biogas Upgrading: The renewable energy sector benefits from gas separation membranes by upgrading biogas to meet pipeline specifications, enabling the integration of renewable gases into existing natural gas infrastructure.

Carbon Capture and Storage (CCS): Gas separation membranes play a pivotal role in carbon capture technologies, selectively capturing carbon dioxide emissions from industrial processes and power plants.

Market Dynamics and Growth Drivers:

Several factors contribute to the growing demand for gas separation membranes:

Stringent Environmental Regulations: Increasing environmental regulations and a focus on reducing greenhouse gas emissions drive industries to adopt cleaner technologies, boosting the demand for gas separation membranes.

Energy Efficiency: The quest for energy-efficient processes and the need to optimize industrial operations are propelling the adoption of gas separation membrane technologies.

Rising Demand for Clean Energy: The global shift towards cleaner energy sources has led to increased interest in gas separation membranes for applications like hydrogen production and biogas upgrading.

Technological Advancements: Ongoing research and development efforts are leading to the development of advanced membrane materials and configurations, enhancing the efficiency and applicability of gas separation membranes.

Conclusion:

The Gas Separation Membranes Market is a key player in the pursuit of sustainable and efficient industrial processes. As industries strive to meet environmental goals and improve operational efficiency, the demand for these membranes continues to soar. From natural gas processing to carbon capture and renewable energy applications, gas separation membranes are at the forefront of driving positive change. As technology continues to advance and markets expand, the gas separation membranes sector is set to play an even more significant role in shaping a cleaner and more sustainable future.