Mask machine is a multi-layer non-woven cloth through hot pressing, folding forming, ultrasonic welding, waste removal, ear and nose welding procedures to produce a variety of masks with certain filtration performance. In the production of masks, multiple layers of materials should be neatly fitted together, otherwise, there will be waste products or even stuck machines. The all-in-one web guiding system manufactured by Arise can realize multi-layer material alignment, double the speed, free of waste in the refueling process, and no machine sticking.

What Is The Web Guiding System

The web guiding is a system that controls the position deviation of the coil material in the production line when it is conveyed. The machine has the functions of automatic detection, automatic tracking, and automatic adjustment. It can track and control the marking lines, edges of the paper, film adhesive tape, aluminum foil and other materials to ensure the neatness of winding and slitting.

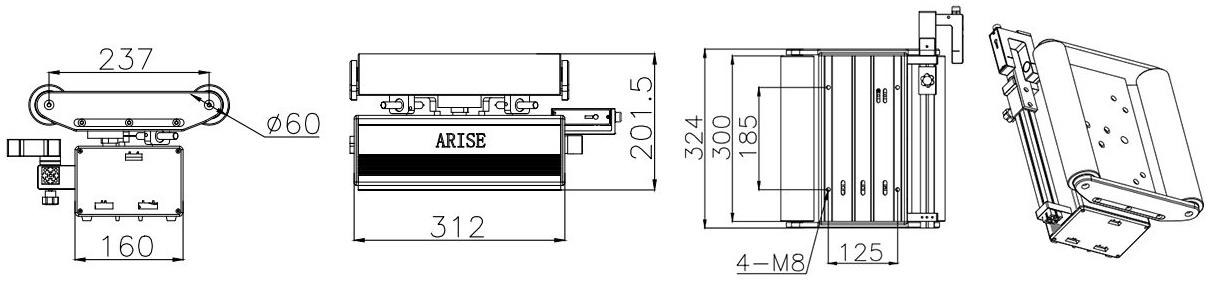

The Arise web guiding system can achieve multi-layer material alignment. The guiding system is a controller for tracking the edge position of the working material or printing lines for high-accuracy differential and swing. It is composed of industrial integrated circuits and has the advantages of strong anti-interference ability in a harsh working environment, high reliability, and long service life.

Advantages Of The Web Guiding System

One-piece design: tightly sealed, compact;

Brushless servo motor drive, maintenance-free

Precision ball screw, accurate positioning

Beautiful appearance: aluminum alloy finishing, surface sandblasting oxidation

Flexible installation: can be integrated, separated and installed, can be installed at any angle

How The Web Guiding System Work

The equipment guides the sensor to emit infrared or ultrasonic to monitor the operation of the coil and send a signal to the controller. After the controller finds that the web has a positional deviation, according to the command preset by the controller, controlling the drive system to swing to correct the web position.

The web guide control system is composed of a controller, a web guide sensor, an electric drive, and a web guide mechanism. These four components together form a closed-loop control system. The sensor detects the edge position of the coil, reading the deviation between the actual position and the set position, converting this deviation into a voltage signal proportional to it, and then sends this signal to the controller. After the signal is amplified and calibrated by the controller, the signal is output to the electric driver which drives the web guide mechanism to perform actions, according to the magnitude of the input signal, to guide the coil to a preset position.

For more professional knowledge, please visit the article pages of the web guiding system