Roofing is one of the most vital components of any building, providing protection from the elements while contributing to its aesthetic appeal. Behind every durable and visually pleasing roof, there is a process of meticulous roofing sheet product manufacturing. In this article, we'll delve into the world of roofing sheet manufacturing, highlighting the key aspects that ensure the creation of top-quality roofing materials.

The Art and Science of Roofing Sheet Product Manufacturing:

- Material Selection: The Roofing sheet product manufacturing begins with the choice of materials. Manufacturers select materials such as metal, asphalt, concrete, or clay, depending on the desired properties and aesthetic requirements.

- Quality Control: Stringent quality control measures are integral to manufacturing roofing sheets. Precise manufacturing processes ensure that each sheet meets industry standards for strength, durability, and weather resistance.

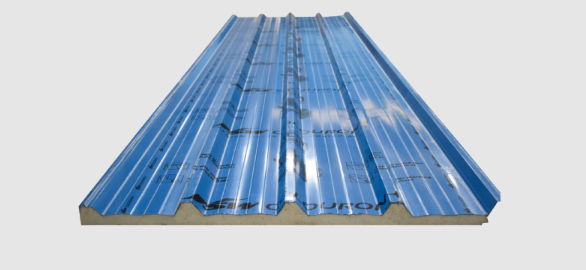

- Design and Profile: Roofing sheet manufacturers offer a variety of designs and profiles to suit different architectural styles and climates. From corrugated to standing seam profiles, options abound.

- Coating and Finishes: Coating technologies provide roofing sheets with added protection against corrosion, UV rays, and extreme weather conditions. Coatings like galvanized steel and reflective coatings enhance longevity.

- Customization: Manufacturers often cater to custom orders, allowing customers to choose colors, finishes, and dimensions that match their specific project requirements.

Advantages of Quality Roofing Sheet Manufacturing:

- Longevity: Well-manufactured roofing sheets are built to last, providing long-term protection and reducing maintenance costs.

- Durability: Quality materials and manufacturing processes ensure that roofing sheets can withstand various environmental challenges, from heavy rain to intense sun.

- Energy Efficiency: Reflective coatings and insulation options can enhance a building's energy efficiency, reducing heating and cooling costs.

- Aesthetics: A wide range of colors and finishes allows for the creation of visually appealing roofs that complement the overall design of a structure.

Environmental Considerations:

- Recyclability: Many roofing sheet materials are recyclable, contributing to sustainability and reduced waste.

- Energy Efficiency: Reflective coatings and materials can reduce a building's energy consumption, making it more environmentally friendly.

Conclusion:

Roofing sheet product manufacturing is a combination of science, craftsmanship, and quality control. The roofing materials produced through this process are more than just protective layers; they are essential components that contribute to the integrity, durability, and energy efficiency of buildings. When choosing roofing materials for your project, consider the reputation of the manufacturer, the quality of materials and finishes, and the ability to customize to ensure that your roofing sheets meet the highest standards and are perfectly tailored to your needs.

For more info. visit us: